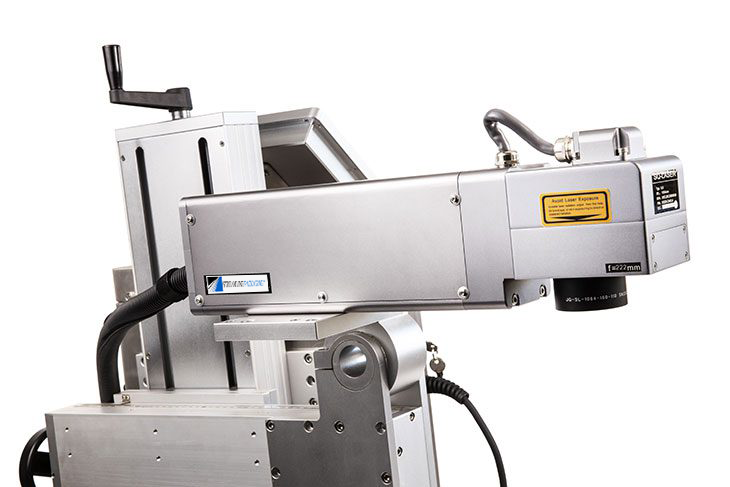

SP50-F-A Fiber Laser Marking System

Streamline Packaging’s SP50-F-A laser coding systems are designed for high speed automotive, electronics, medical, aerospace, beverage, and other primary coding applications. The SP50-F laser can permanently mark onto virtually every common metal including precious metals, stainless and hardened steel, copper, anodized aluminum, and more. It also marks on non-metals such as aluminum foil, PVC, ceramics, plastics, rubber, composite material, and more.

Application Versatility

- Permanent coding of text, time and date, bar codes, serial numbering and more

- Quick and easy installation for both stationary and moving products

- Compact design easily fits into production environments where space is limited

- Can be integrated in production lines at speeds up to 300m/min

- Laser head can be rotated 90° in less than 5 minutes

We have inks and fluids for all of our printing equipment!

Optional Heavy Duty Stand

Rotating 90 Degrees

10″ Touchscreen Software

Key Switch & Interlock Relay

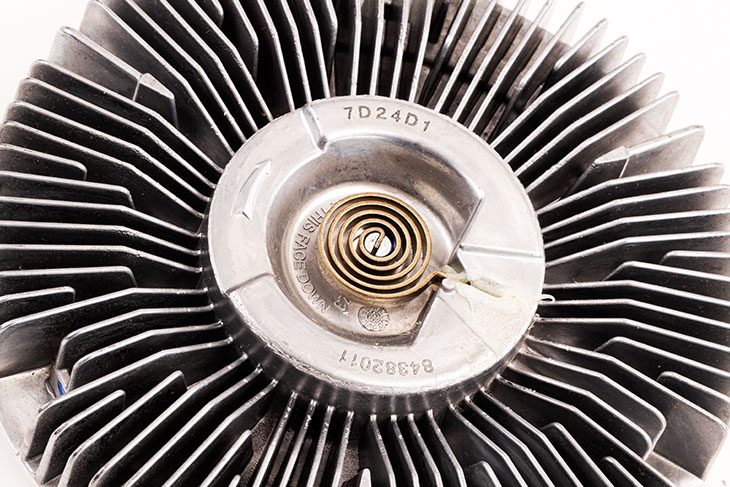

Printing Samples

Optional Accessories

- Print Trigger: Optical, fiber optic, ultrasonic, laser, metal proximity, capacitive proximity

- Encoder: For operation with variable speed conveyors

- Mobile Stands: Heavy duty stand with ability to rotate laser controller in any direction and easily raise and lower marking machine by a single operator; includes casters for easy transportation within plant

- 90 Degree Head Pivot Extension: Mirror assembly that allows marking head to point lens in line with unit axis

- Laser Fume Extraction Systems: SP-LFX or SP-LFX PVC for the proper extraction of laser application fumes

- Installation and Training: On-site installation and training available

System

- System Specifications

- Laser Type: 50W fiber laser source

- Laser Wavelength: 1.064μm (1064nm)

- Laser Galvanometer: High-precision 2-dimensional high-speed scanning method

- Controller and Operating System: 10” touchscreen controller running Linux®

- Cooling Method: Air-cooled

- Power Consumption: <500W

- Marking Area: 110mm x 110mm standard, optional lenses up to maximum 500mm x 500mm

- Reflector Size: 8.5mm

- Production Line Speed: 0 – 300m/min (varies according to substrate and message)

- Marking Speed: up to 1200mm/s

- Character Size: Adjustable in marking area, no character line limits within marking area

- Marking Line Number: Code Rotation – 0 to 360°

- Drawing Types: Dot matrix and vector

- Positioning Method: Red light positioning and auto focusing for simple setup

- Software Features: Counter, lot counter shift code, time and date, expiration date, 2D and linear bar codes

- Bar Code Symbologies: Code128, Code39, Code93, EAN13, PDF417, 01Code, QR, DataMatrix, GS1-DM, AztecCode, HanxinCode, DotCode

- Image Formats: bmp, dxf, jpg, plt, png

- Operating Languages: English, Chinese, German, Spanish, French, Italian, Japanese, Korean, Portuguese, Hindi, Russian, Turkish, Arabic, Persian

- Safety Features: Integrated key switch and interlock relay included for safety on the production floor; customer provided shielding necessary to prevent eye or skin exposure

- Interfaces: RS-232C, USB2.0, Ethernet, I/O

- Machine Material: Anodized aluminum (marking head) and stainless steel (control unit)

- Laser Head Dimensions: 18” (458mm) x 3.3” (83mm) x 4.4” (111mm)

- Controller Dimension: 19.4” (492mm) x 15” (383mm) x 6.3” (160mm)

- Electrical Requirements: 90 – 240 VAC, 50/60Hz

- Operating Environment: 32°F – 113°F (0°C – 45°C)

- Humidity Range: 10 – 90% relative humidity, non-condensing

- Machine Weight: 68.4 lbs. (31kg)

- Agency Approval: CE Mark

Reliable & Economical

- No ink/consumables and near zero maintenance for lower cost of ownership

- Clean and eco-friendly coding system features low energy consumption

- Rugged cast aluminum controller body

- IP54 rating ensures maximum reliability and uptime in demanding applications

- Integrated key switch and interlock relay for increased safety on the production floor

High Quality Code Generation

- Scribing technology produces razor sharp marks on a variety of substrates including metal, ceramics, plastics, and more

- Ability to mix different fonts and logos in a single message

- Discrete coding ability for anti-counterfeiting and traceability

- Ideal coding alternative where CIJ systems are not practical

Easy to Start, Simple to Run

- All-in-one design for fast installation and line changes

- Easy to use software with smart touchscreen panel

- Removable 10″ tethered touchscreen controller for remote mounting where space is limited

- Intuitive system includes focus finder and code area preview window on product during setup; enables initial laser marking setup within minutes

- Easily configurable in a variety of angles with optional mobile stand

- Optional fume extraction systems available that connect directly to SP-Laser systems

Replacement Inks and Fluids

Replacement Inks and Fluids