Auto Uniform Case Taper

The SSB-2EX Auto is an automatic uniform side belt case taper designed to close all four top case flaps and seal the top and bottom of each case. The adjustable plow system provides the utmost flexibility for varying types of carton sealing applications and provides a great alternative to hand taping. The SSB-2EX Auto will seal up to 20 cases per minute.

The SSB-2EX Auto will accept cartons from a powered conveyor and will automatically close the top carton flaps. A rugged stainless steel plow folds down the front panel, while a rear kicker folds down the trailing minor flap prior to the major flaps being folded. The SSB-2EX Auto automatically meters cartons with a photoeye controlled drop conveyor gating system. Top squeezing rollers help keep the major flaps together while keeping the carton square prior to tape application.

SSB-2EX Auto offers fast and easy case changes and flexibility for boxes 5” to 24” in length. The adjustable hand cranks can be moved to either side of the machine and allow for quick carton change over. This feature allows you to locate either side against a wall, while being able to maintain control of the adjustments from the opposite side. SSB-2EX Auto utilizes Streamline Solutions’ EX Quick-Load top and bottom tape cartridges and will seal boxes as narrow as 4.5” wide and as low as 5.0” tall.

Features

- Utilizes Streamline Solutions’ EX tapehead

- Plug-In and go operation

- Powder coated 12 gauge steel

- Adjustable side guides

- Industrial strength side belts

- Drop conveyor gating system

- Interlock safety gates in the kicker stationensions

- Adjustable leg extensions

- Fast and easy box size changes

- Low maintenance operation

- Accommodates wide case range

- Casters for transportation within plant

Options

- 3” Tape Head – Accepts 3” wide tape rolls

- Rear Roller Table – Roller table bolts after taping system to allow for case movement

Taping Specs

- Sealer Type – Fully automatic uniform side belt, top and bottom case sealer

- Machinery Makeup – Industrial strength 12 gauge steel, powder coated for durability

- Belt Speed – 75 feet/per minute (23 meters/minute)

- Tape Speed – 20 cases/per minute, depending on box size and operator efficiency

- Height Adjustment – Standard adjustable legs for 27” (685.8mm) to 34.6” (878.8mm) conveyor heights

- Tape Size – 2” wide pressure sensitive tape, up to 15” diameter rolls, optional 3” wide tape

- Tape Cartridge – Proven design requires no lubrication, tips back for simple tape threading, removable for maintenance and interchangeable with top or bottom cartridges

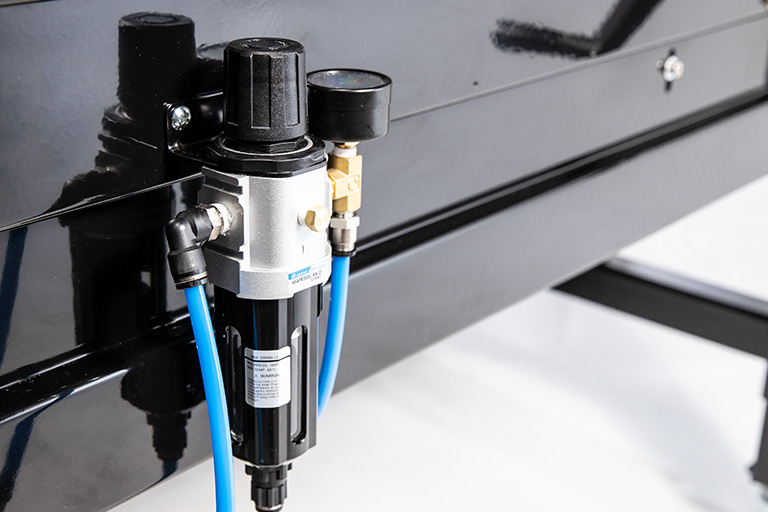

- Air Requirements – 85 psi

- Electrical Requirements – 110 VAC, 60Hz, 4.0A

- Agency Approvals – CE Certification

Box Specs

- Minimum Box Size – 5” (120mm)(Length) x 4.5” (110mm)(Width) x 5.0″ (120mm)(Depth)

- Maximum Box Size – 24” (610mm)(Length) x 19.5” (500mm)(Width) x 19.5” (500mm)(Depth)

Adjustable Front Flap Plow

Adjustable Rear Kicker

Adjustable Side Rails & Tape Heads

Identical Top & Bottom Tape Heads

Product Sensors Trigger Drop Infeed

Indexing Drop for Spacing

Easy Access Power & Operations

Adjustable Crank for Quick Change

Easy Air Line Connect/Disconnect

Easy Access Electrical Box

Top Rollers to Keep Flaps Together

Fast & Easy Changes